Why Is a Medical Packaging Bag So Essential for Modern Healthcare Safety and Sterility?

2025-10-30

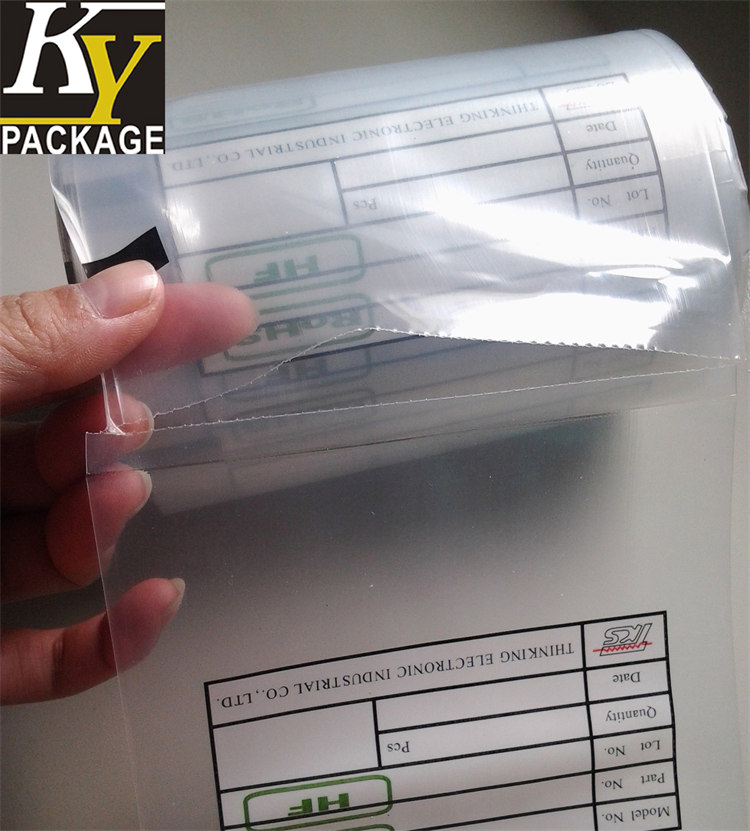

In today's healthcare industry, the importance of reliable, hygienic, and durable packaging cannot be overstated. A Medical Packaging Bag serves as a protective layer between medical instruments, pharmaceuticals, and external contaminants. It ensures that every item—from surgical tools to diagnostic supplies—remains sterile and ready for safe use. As a professional supplier, Kaiyu Package Industry Co., Limited is dedicated to producing high-performance Medical Packaging Bags that meet international medical safety standards, offering both functionality and peace of mind.

What Is a Medical Packaging Bag and Why Is It Crucial in the Healthcare Field?

A Medical Packaging Bag is a specialized type of packaging designed to protect medical devices, pharmaceuticals, and instruments from contamination, moisture, and mechanical damage. It plays a vital role in maintaining sterility during transportation, storage, and handling. These bags are widely used in hospitals, laboratories, clinics, and pharmaceutical industries.

Medical packaging bags are often made from multilayer composite films that combine polyethylene (PE), nylon (PA), or medical-grade paper and film. The structure provides excellent tensile strength, chemical resistance, and puncture protection. They can also be customized to fit various sterilization methods, including ethylene oxide (EO) sterilization, gamma radiation, or steam autoclaving.

When I first began exploring medical-grade packaging, I wondered: Can such a simple bag truly make a difference in healthcare safety? The answer became clear after witnessing how contamination control directly affects patient outcomes. Reliable packaging literally saves lives.

How Does a Medical Packaging Bag Work to Protect Sterility?

The working principle of a Medical Packaging Bag revolves around creating a sealed barrier that prevents microorganisms, dust, and other contaminants from entering. These bags often feature:

-

Heat-sealable closures to ensure airtight sealing.

-

Transparent windows for easy identification of the contents.

-

Strong multilayer films that resist tearing or puncturing during handling.

-

Compatibility with sterilization—allowing the bag and contents to be sterilized together.

The structure of each bag is meticulously engineered to withstand extreme sterilization environments while maintaining the integrity of the seal and film. Once sealed, the packaging bag preserves sterility until the moment it is opened in a controlled medical setting.

What Are the Key Specifications and Parameters of a Medical Packaging Bag?

Below is a simplified table outlining the main parameters and customizable options of our Medical Packaging Bags from Kaiyu Package Industry Co., Limited:

| Parameter | Specification | Description |

|---|---|---|

| Material Composition | Medical-grade PET/PE, PA/PE, or Paper/Film | Ensures high transparency and barrier protection |

| Thickness Range | 60–120 microns | Adjusted for durability and sterilization type |

| Available Sizes | Customized (width 80–600 mm, length up to 1000 mm) | Fits various instruments and devices |

| Sterilization Compatibility | EO, Steam, Gamma | Supports multiple sterilization processes |

| Printing Options | Up to 8 colors | Custom logo or instruction printing available |

| Sealing Method | Heat-sealed or self-adhesive | Provides secure and contamination-free closure |

| Certification | ISO 13485, CE | Meets international medical standards |

These parameters can be adjusted according to customer needs. For instance, clients who require higher oxygen barriers or moisture protection can choose a multilayer nylon composite film, while those focused on disposables might opt for a simpler PE structure.

Why Should Healthcare Providers Choose Our Medical Packaging Bag?

When it comes to medical packaging, quality and reliability determine patient safety. Kaiyu Package Industry Co., Limited provides an advanced production line that integrates precise lamination, cleanroom manufacturing, and strict quality control systems. Here's why our Medical Packaging Bags stand out:

-

Superior Material Quality: All materials are sourced from medical-grade suppliers to ensure compliance with FDA and EU standards.

-

Cleanroom Manufacturing: Production takes place in a Class 100,000 cleanroom to prevent contamination.

-

Customizable Design: Size, thickness, printing, and sterilization compatibility are fully customizable.

-

Eco-Friendly Options: We offer recyclable and biodegradable film structures to reduce environmental impact.

-

Global Export Experience: We supply to clients across Europe, Asia, and the Americas with fast delivery and professional after-sales support.

When I discuss with medical equipment manufacturers, many ask, Can customized packaging really improve efficiency? The truth is, tailored Medical Packaging Bags reduce waste, improve storage efficiency, and ensure faster sterilization cycles—directly saving costs and time.

What Are the Common Applications of Medical Packaging Bags?

Medical Packaging Bags have a wide range of applications, including but not limited to:

-

Surgical Tools and Instruments: Sterile packaging for scalpels, scissors, clamps, and more.

-

Pharmaceutical Packaging: Protection for tablets, injectables, and diagnostic test kits.

-

Disposable Medical Supplies: Ideal for gloves, syringes, gauze, and masks.

-

Laboratory Equipment: Safe containment of reagents, pipettes, and sample bags.

Each application requires unique barrier properties, sealing strength, and sterilization compatibility—all of which can be tailored by Kaiyu Package Industry Co., Limited.

FAQ: Everything You Need to Know About Medical Packaging Bags

Q1: What materials are used to make a Medical Packaging Bag?

A1: Medical packaging bags are typically made from laminated structures such as PET/PE, PA/PE, or medical-grade paper and film. These materials provide transparency, strength, and resistance to moisture and chemicals, ensuring long-term sterility.

Q2: Can Medical Packaging Bags be sterilized?

A2: Yes. Our Medical Packaging Bags are compatible with multiple sterilization methods including ethylene oxide (EO), gamma radiation, and steam autoclaving. The material structure is selected according to the sterilization process used.

Q3: How can I choose the right type of Medical Packaging Bag for my products?

A3: The right choice depends on your product type, sterilization method, and storage environment. Our team at Kaiyu Package Industry Co., Limited can provide customized guidance to select the ideal thickness, material, and sealing option for your application.

Q4: Are Medical Packaging Bags recyclable or eco-friendly?

A4: Absolutely. We offer recyclable polyethylene-based materials and can design biodegradable options upon request. This supports hospitals and manufacturers aiming for sustainable packaging solutions.

Why Is Choosing the Right Medical Packaging Bag So Important?

The choice of packaging in the medical industry is not merely aesthetic—it directly impacts product safety and compliance. A poorly designed or low-quality Medical Packaging Bag may result in contamination, regulatory issues, or even patient harm. By contrast, using high-grade, certified packaging ensures every medical product arrives sterile, safe, and ready for use.

In my experience working with hospitals and medical suppliers, I've seen how investing in premium packaging dramatically reduces waste, product recalls, and infection risks. When safety, compliance, and reliability are non-negotiable, only professional-grade packaging will suffice.

Conclusion

A Medical Packaging Bag is far more than a simple container—it's an essential component of modern medical logistics and infection control. Choosing the right bag means choosing safety, efficiency, and reliability for both patients and medical professionals.

If you're looking for a trustworthy manufacturer to supply premium-quality Medical Packaging Bags, Kaiyu Package Industry Co., Limited is ready to provide customized solutions tailored to your needs.

Contact us today to learn more about our full range of medical packaging products and experience the confidence that comes with quality you can trust.